Storage tank completely made from quality stainless steel

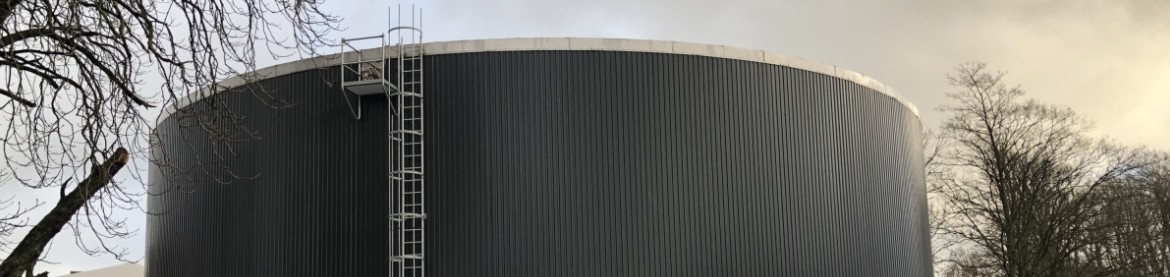

The biggest glycerin tank is now integrated in a biogas plant in Hammel, Denmark. The tank can cover 4.500m³ glycerin which is stored in a fully insulated storage tank made from long-lasting stainless steel.

Modern storage tank

The glycerin tank was added to an existing biogas plant with a power of two Megawatt. The storage tank has a diameter of 25m and is almost 9m tall. The construction is based on stainless steel shell plates which are assembled in a segment-like design. Seven rings of the shell plates are necessary to reach the height of 9m. In terms of the material, the lower five rings are made from stainless steel 1.4462 and the upper two rings from stainless steel 1.4571. The top part of the tank needs to be more resistant to corrosion. Therefore it was decided to use different types of stainless steel in the tank.

Stainless steel roof

The tank is covered with a stainless steel roof pillared by a central support. Being composed of an inner and outer screwed element, the outer ring is attached to the top of the tank, whereas, the inner ring is posed higher. Thus, a decline of 10° occurs. The roof is designed for insulation and cladding and is completed by two inspection openings.

Attachments and security

The tank is equipped with a heating system including full insulation. Thus, the glycerin can be constantly stored at 40°C and pumped into the fermentation process whenever necessary. The tank has two wall bushings, two working platforms with ladders for security reasons and three powerful submersible motor agitators in stainless steel.

Glycerin as a powerful source for biogas

Glycerin is the basic input of the plant and it has huge energetical power. The substance is waste from the production of biodiesel. With a pH value between 3,5 and 8 and a density of 1,3 kg/l, the glycerin is heated up to 52° in the digester and the anaerobic process starts. Glycerin is considered to be the most valuable input for the fermentation process because the bacteria transform almost all of the glycerin. Thus, there are almost no fermentation residues. A comparison between the output of corn and glycerin illustrates the energetic value of glycerin. General indicating numbers say that one ton of corn yields to 200-250 m³ gas, whereas, glycerin yields to 1.000 m³ gas.

Assembly and construction of the stainless steel tank

A very crucial part of the project was the assembly and construction phase on site due to the enormous size of the tank including the roof. The first step was the assembling of the first ring and the installation of the roof. Afterwards, the top part of the digester was electrically lifted up. 40 pillars are necessary to lift up the whole construction including the central support. Then the second ring was assembled and the tank was lifted several times until the seventh ring was constructed.

Why stainless steel?

It was a simple decision explains the plant owner. We decided for stainless steel because it is the most durable material in terms of corrosion. And the decision for Stallkamp was easy as well. With the experienced and reliable distribution partner Biogas Teknik A/S, we knew that this project would going to be a success.

Technical Data

| Diameter: | 25m |

| Height: | 9m |

| Volume: | 4.500m³ |

Location

8450 Hammel, Denmark

Project realisation: Biogas Teknik A/S

Please contact Erich Stallkamp ESTA GmbH for any further information.

https://www.stallkamp.de/en/references/biggest-glycerin-storage-tank-in-denmark#sigProId974667b79e