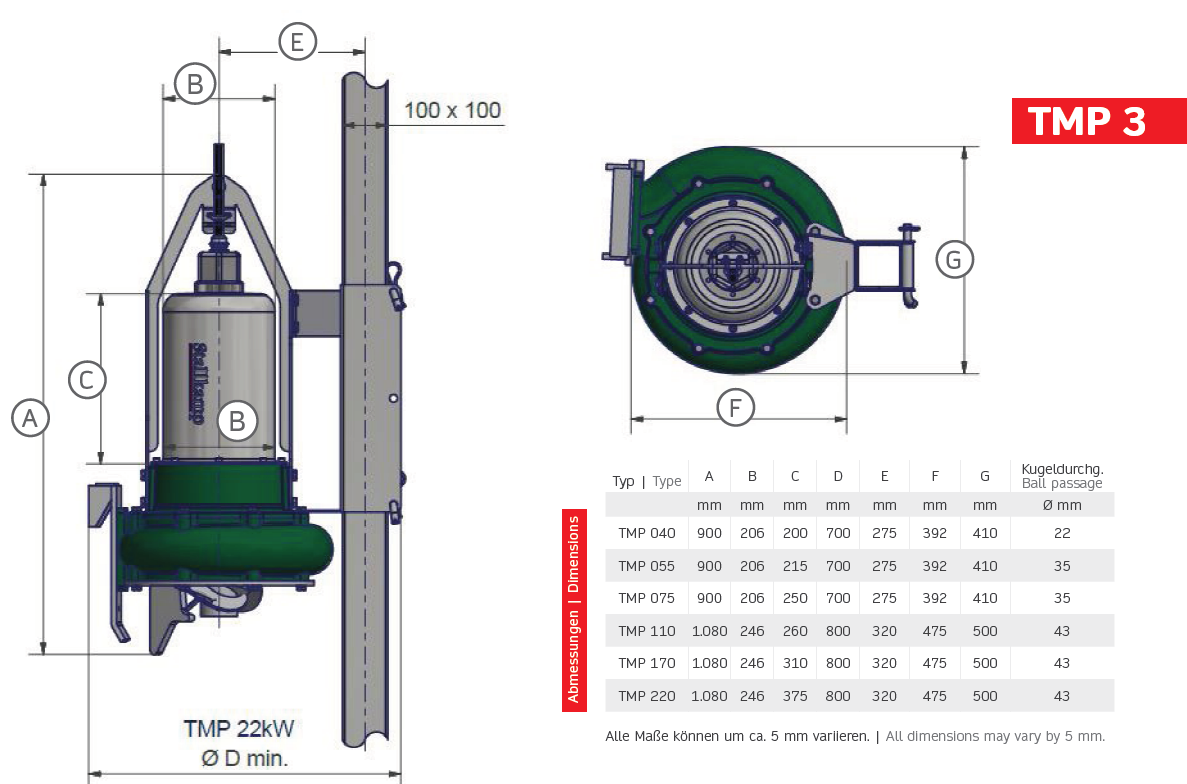

Our Submersible Motor Pump at a glance

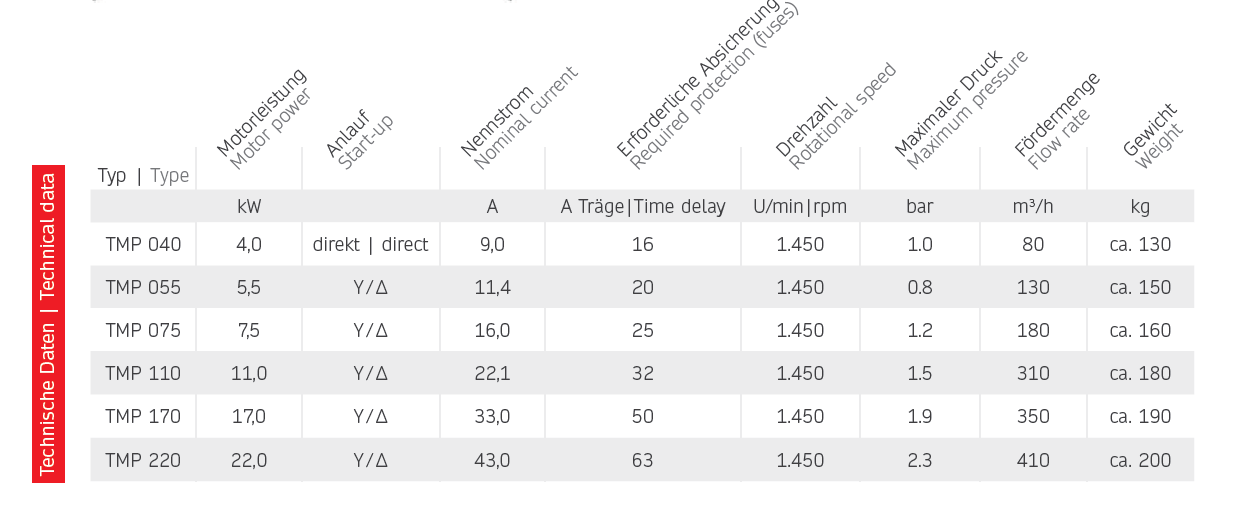

- Electric motor 4,0 – 22,0 kW

- Three-phase-motor 400 V, 50Hz, 1450 rpm.

- IP68 protection category, insulating category F = 155° C

- Thermo control for each phase as overheating protection

- Motor housing in 1.4301 stainless steel

- Pump housing made from cast iron material coated with 2-component plastic lacquer

- Large pump housing and therefore resistant to blockages

- Pump impeller with intake auger and chopping mechanism with tungsten carbide wear protection

- Galvanized steel suction plate with cutting edges and winding protection

- Sealed with radial shaft seal rings on special acid-resistant hardened rings

- Electric cable with water-blocking devices in the longitudinal direction of the cable for moisture protection;special PU outer sheathing with moulded connection

- 1.4301 stainless steel slide bearing and absorb flange

- Electric switch as a manual star-delta or automatic star-delta starter with motor protection switch and CEE plug

- Pumping manure in repository slurry storage tanks, slurry canals and reception pits

- Pumping biomass for biogas systems

- Pumping sewage sludge in wastewater treatment plants

- Pumping industrial wastewater in industrial systems

- Top performance under tough conditions (application in manure and biogas plants)

- Spiral shaped shearing edge and large volume housing to prevent blockages

- Thermo-control is installed as standard to prevent damage from overheating

- Pumping medium temperature up to 50° C

- The smooth design prevents the accumulation of fibrous materials

- Space-saving design

- A wide range of accessories

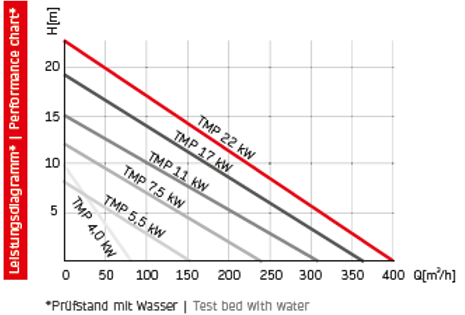

The flow rate (volume flow rate in m³) is dependent on the density and viscosity of the liquid, the type and the DM content of the manure (animal feed), the support height and distance and the diameter of the pipeline.