16.09.2020 - Stallkamp enlarges its separation portfolio by a new fully-equipped mobile unit.

The investment even pays off for small separation amounts.

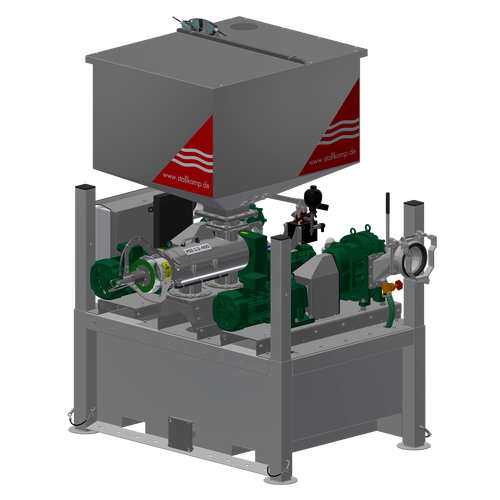

Established technology newly combined

The Stallkamp press screw separator showed reliable separation results with cow and pig manure. With a driving power of just 2,2 kW the medium is filteres through the sieve basket. Depending on the medium you can choose between basket sizes of 0,35 and 1,00 mm. This leads to a throughput of min. 2-12 m³/h.

The components

The fully-equipped separator is comprised of seven main components:

- Rotary lobe pump sucks the slurry

- Hopper is filled with medium

- Rotary lobe pump conveys the thin manure

- Separator presses out the liquids

- Hopper collects the thin manure

- Control panel monitors the components

- Adjustable pillar

Simple Application

The new unit is designed for farmers with a tight schedule. Having started the machine the separator at the press of the button because the pumps are automatically controlled. The slurry separator is also affordable for enterprises with smaller live stock. The costs for the whole machine account for roughly 35.000 €.

Easy to maintain

The hydraulic ball head is a highlight of the Stallkamp press screw separators. The desired degree of dry matter can be adjusted by a hydraulic hand pump. By help of a hinge, it is very easy to remove the ball head to maintain the press screw and the sieve basket. Contact us here for more information!